Vacuum glazing has demonstrated superior performance far beyond double glazing in noise reduction,anti-condensation ,thermal insulation etc.

There are three types of heat transfer existing in the central area of a vacuum insulated glass: transfer through radiation, spacer, and residual air. For a quality vacuum insulated glass product, heat transferred through residual air is negligible. In comparison, insulating glass transfers heat through both air (conduction and convection) and radiation.A 8.3 mm thick Landvac vacuum glazing has better thermal insulation effect than the 1.5m thick brick wall.Compared with double glazing, the energy consumption per unit of floor area is reduced by approximately 20% .

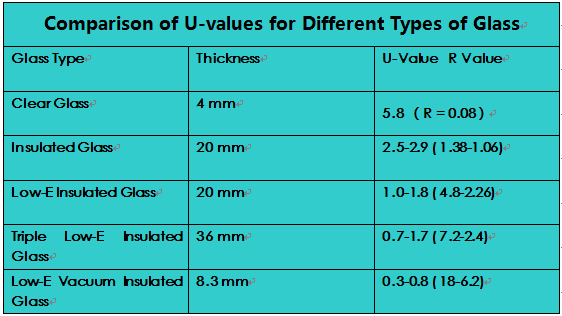

2. U-value: Low-E vacuum glazing is more cost-effective

3. Installation positions: Vacuum glazing can be installed on the inclined roof or flat skylight

Insulating glass usually has its interspace filled with gas. When installed horizontally, its U-value rises due to the increase of gas convection.Furthermore, unlike insulated glass, whether it’s mounted horizontally or at an angle, the U-value of LandVac vacuum glazing remains constant, which ensures excellent energy-saving effect,especially suitable for skylights, sunroom, daylighting roof, and applications in other special spaces.

4. Thickness and weight: Vacuum glazing is thinner and lighter

A piece of 8.3 mm thick LandVac vacuum glazing weighs only 20kg/㎡. It reduces the use of materials while extending the service life of hardware. The costs on storage and logistics are also significantly reduced.

5. Noise Reduction: The noise redution performance of vacuumglazing in mid to low-frequency range is far better than double glazing.

Weighted sound reduction≥39dB, which is 1.5 times that of ordinary insulated glass

6. Anti-condensation Performance: Vacuum insulated glass demonstrates great resistance to internal condensation

Condensation refers to the phenomenon where condensed water droplets form on the surface of an object when its temperature drops below the dew-point. As the vacuum glazing has its edges sealed all around, the vacuum chamber eliminates the possibility of condensation and keeps the glass surface temperature of the indoor side above the dew-point. For instance, in an environment where the indoor temperature is at 18℃with with relative humidity at 60%, the dew-points on the inner surface of insulating glass and vacuum insulated glass are -8℃and -36℃, respectively. It makes the vacuum insulated glass more suitable for applications in regions with extremely cold weather.

7. Sealing performance and useful life: Vacuum insulated glass has a longer life than other glass.

Insulating glass commonly employs a dual-sealing structure with metal spacers. The inner layer of sealant is made of butyl rubber covered by an outer layer of silicone or polysulfide sealant. These materials age easily. In comparison, most vacuum insulated glass is sealed with solder glass and can last much longer. In general, the average service life of insulating glass is about 15 years, while vacuum insulated glass can serve more than 25 years.